Baumer hhs launch their FFG adhesive application system Inverto

- Publicado el 02 de Marzo de 2017

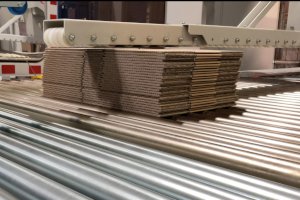

Under the name Inverto, Baumer hhs is extending its product range for application on flexo-folder-gluers (FFGs) by bringing a new gluing unit for non-contact adhesive application to the market that will enable corrugated packaging producers to increase their flexibility in the case of both retrofits and new machines. By rapidly switching gluing from top-down to bottom-up, the innovative system makes it possible to glue both inner and outer flaps when converting corrugated board on flexo-folder-gluers.

A decisive economic advantage in this context is that Inverto manages with just one adhesive application head and a single traversing drive unit – this also minimising the installation effort and the complexity of the system within the FFGs. Moreover, the process of switching gluing from top-down to bottom-up is very convenient and takes very little setup time.

"Outer flap gluing is frequently used when producing corrugated boxes and other packagings made of corrugated board, in order to make optimum use of the volume of the packagings. With Inverto, processors of corrugated board can upgrade their FFGs to include this option, without having to install a second drive unit in their FFGs. The investment costs are low, and only little installation effort is required. We developed this gluing unit for alternating adhesive application from above and below in response to requests from numerous customers, particularly for retrofitting on existing FFGs," explains Andreas Schneiders, Branch Manager FFG at Baumer hhs GmbH in Krefeld, Germany.

Inverto consists of a standard system, comprising an application head, a set of cables and a blank guide. In addition, Inverto optionally has two tried-and-tested MLT 40 sensors for 100% monitoring of adhesive application, both from above and from below. The time-proven water bath, familiar from Baumer hhs gluing systems, protects the adhesive application heads when gluing from above, the heads being "parked" in the water bath when the FFG is idle.

In keeping with the demand of the corrugated industry for minimum setup times, Baumer hhs paid attention to simple switching of gluing from top-down to bottom-up and vice versa when developing Inverto. Consequently, innovative quick-action locks are used to simplify the switchover – the application head merely has to be released, repositioned, and locked in place again. The whole procedure takes next to no time. Equally, gluing and the optionally installed monitoring system can also be switched over in a matter of seconds on the intuitive touch screen of the Xtend2 controller from Baumer hhs. Both features guarantee the shortest possible setup times and thus maximum availability of the FFGs.