New innovations and market trends highlighted at BOBST and partners roadshow held in Taiwan

- Publicado el 24 de Febrero de 2017

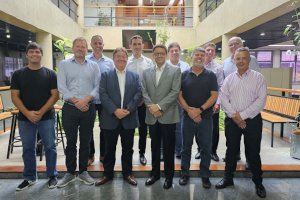

This edition of the BOBST and Partners roadshow held in Taipei on 14th December attracted 140 participants from 70 companies in the printing and packaging industry to hear about the latest innovations and trends in flexible packaging and labels. The well-established format brings together industry leaders from around the world who are driving innovation in the development and expansion of printing processes in the global flexible packaging and labelling industry.

Throughout the day, BOBST covered flexographic, gravure, coating, laminating, metalization and in-line narrow web printing processes and introduced various printing and converting equipment to help the Taiwanese manufacturers to innovate in the area of production technology and to improve efficiency, reduce operating costs and thus increase profits. Additionally, partners including Henkel, DuPont, Schmid Rhyner, Flexo Wash, Macchi and Daetwyler discussed market trends and solutions in their respective fields, covering the areas of production, printing, converting and finishing.

Guests showed particular interest in BOBST’s flexo, gravure and lamination equipment. The RS 5002 gravire press for shaftless cylinders combines the advantages of BOBST leading–edge technology with features dedicated to meet the specifics of gravure printing for flexible packaging in Asia. In coating, BOBST production lines for applications in the segments of paper and film coating, aluminium foil lacquering, barrier coating for films and technical coating provide highly efficient custom-made solutions. The AlOx and SelectMet® technologies from the vacuum metallizing division were also well received. Feedback from participants was good and the topics presented were seen as very relevant to the latest trends in the packaging industry today.

“Taiwan is an important market for us, although it is only a medium-sized market, the packaging and materials industry in Taiwan is one of the most impressive in Asia, with the most potential and is very mature in terms of quality and added processes for packaging. BOBST technology and latest innovations in printing and barrier processes are a good fit for actual and future requirements from the Taiwanese market. Hot topics being discussed currently include extended gamut in printing, high quality flexo print and coating and high quality metallization”, commented Eric Pavone, Business Development Director of BOBST Business Unit.

He continued, “Over the past few years, demand for BOBST products in Taiwan has continued to increase with Taiwanese companies beginning negotiations with BOBST for various types of printing presses and material processing/converting equipment. We believe the opportunity in Taiwan has arrived and along with our new agent, Mr Willy Yang from IFC, BOBST is looking to continue to expand business in the Taiwanese flexible packaging market and build on the growth which has enabled high-scale product launches in Taiwan for the first time. When there is a need for a product, the demand for materials is bound to be generated; with the progress of the printing and converting process, materials must also meet environmental sustainability and processing adaptability, we believe that BOBST equipment can provide high quality material processing equipment to help the Taiwan market”. Following the roadshow, a high number of new investment projects have been identified and discussed with BOBST and partners’ sales managers. Due to the success of this event, a second event is planned for 2018.